Understanding Silicone Rubber Membranes: A Comprehensive Guide

In the world of modern manufacturing and industrial applications, silicone rubber membranes have emerged as a pivotal component across various sectors. Their unique properties make them invaluable in a multitude of applications, particularly in vacuum systems. This article explores the intricacies of silicone rubber membranes, their benefits, applications, and why they should be your go-to choice for high-performance solutions.

What are Silicone Rubber Membranes?

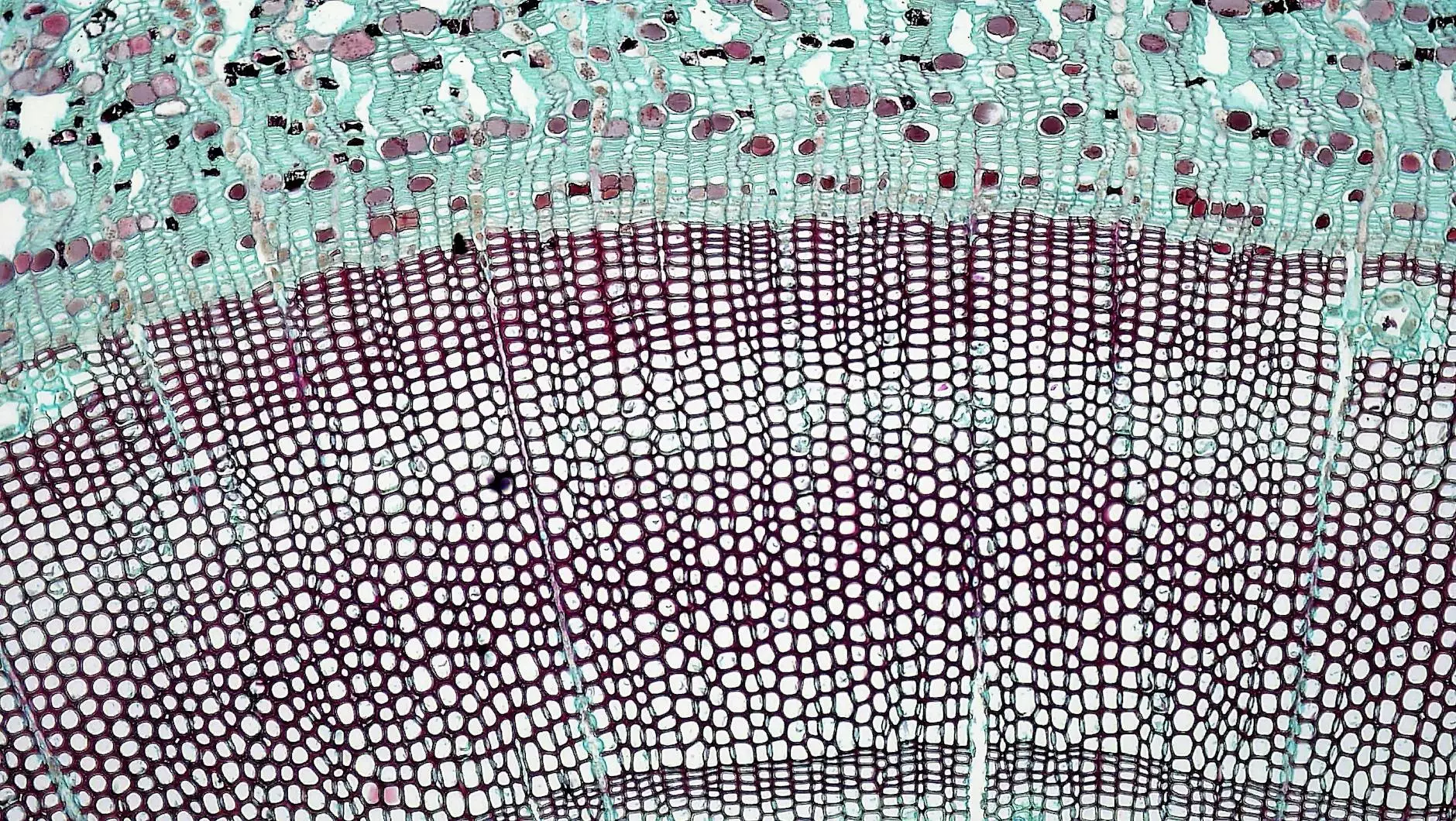

Silicone rubber membranes are flexible and durable sheets made from silicone compounds. These membranes are engineered to perform under a wide range of temperatures and environmental conditions, making them suitable for diverse applications.

Key Characteristics of Silicone Rubber Membranes

- Temperature Resistance: Silicone can withstand extreme temperatures, typically ranging from -55°C to 300°C without losing its properties.

- Chemical Stability: Silicone rubber membranes exhibit excellent resistance to ozone, UV radiation, and a variety of chemicals, ensuring longevity and reliability.

- Flexibility: These membranes maintain exceptional flexibility, which is crucial for applications requiring precise movements or varying shapes.

- Non-Toxicity: Silicone materials are safe for food contact, making them ideal for culinary applications.

Applications of Silicone Rubber Membranes

The versatility of silicone rubber membranes opens up numerous possibilities across different industries. Here are a few prominent applications:

1. Vacuum Systems

Silicone rubber membranes play a critical role in vacuum systems, such as vacuum presses, where they create airtight seals necessary for efficient operation. The durability and flexibility of silicone membranes ensure that they can handle the dynamic pressure changes associated with these systems.

2. Medical Devices

In the healthcare sector, silicone rubber membranes are used in a variety of medical devices due to their biocompatibility and non-reactive nature. Applications include:

- Surgical instruments requiring sterilization

- Drug delivery systems offering precise dosing

- Elastic membranes for respiratory devices

3. Food Processing

Given their non-toxic nature, silicone rubber membranes are increasingly utilized in the food industry for applications such as:

- Packing and sealing food products

- Food processing machinery that requires stringent hygiene standards

4. Automotive Industry

Silicone membranes are also prevalent in the automotive sector, where they contribute to applications requiring resistance to heat, oil, and chemical exposure. Examples include:

- Seals and gaskets for engines

- Vibration isolators

The Benefits of Using Silicone Rubber Membranes

When it comes to choosing materials for industrial applications, the benefits of silicone rubber membranes stand out:

- Longevity: Their resistance to aging and environmental factors leads to a longer lifespan than traditional rubber.

- Better Performance: Silicone membranes maintain their mechanical properties over a wide range of temperatures, ensuring consistent performance.

- Easy Fabrication: Silicone rubber can be easily molded into complex shapes, making it ideal for custom applications.

- Cost-Effectiveness: Though the initial investment may be higher, the longevity and low maintenance of silicone membranes lead to reduced overall costs.

Choosing the Right Silicone Rubber Membrane

Selecting the appropriate silicone rubber membrane involves considering several factors:

1. Thickness and Shore Hardness

The thickness of the membrane affects its strength and flexibility. Shore hardness refers to the material's hardness level, typically measured on the Shore A scale. Depending on your application, you can select a thickness and hardness that suit your needs.

2. Chemical Compatibility

It’s crucial to consider the environment in which the silicone rubber membrane will be used. Ensure that the material is compatible with any chemicals it may encounter to prevent degradation.

3. Temperature Range

Different silicone rubber membranes come with various temperature tolerances. Choose a membrane that can sustain the operational temperatures you require.

How to Purchase Silicone Rubber Membranes

To get started on your journey of utilizing silicone rubber membranes, you can visit vacuum-presses.com. Here, you will find a wide selection of membranes tailored to meet specific industrial needs.

- Custom Sizes and Styles: Many suppliers offer customization options to match your precise requirements.

- Bulk Ordering: Purchase in bulk to save costs and ensure you have enough material for upcoming projects.

- Expert Consultation: Many websites provide expert guidance to help you select the most suitable membrane.

Maintenance of Silicone Rubber Membranes

Proper maintenance can significantly extend the life of silicone rubber membranes. Here are some best practices:

- Regular Inspection: Frequently check membranes for any signs of wear or damage.

- Cleaning: Use appropriate cleaning agents to remove contaminants, especially for food-grade applications.

- Storage: Store membranes in a cool, dry place away from sunlight to prevent degradation.

Conclusion

Silicone rubber membranes are an exceptional choice for businesses looking to enhance their operational efficiency with reliable, versatile, and durable solutions. From their various applications in vacuum systems to their key roles in the medical and food industries, these membranes represent the future of material technology. For businesses interested in sourcing high-quality silicone rubber membranes, look no further than vacuum-presses.com. With their expertise and extensive inventory, you can find the perfect silicone rubber membrane to meet your specific needs.