Are Handmade Cars Made Using Robotics? Exploring the Future of Automotive Manufacturing

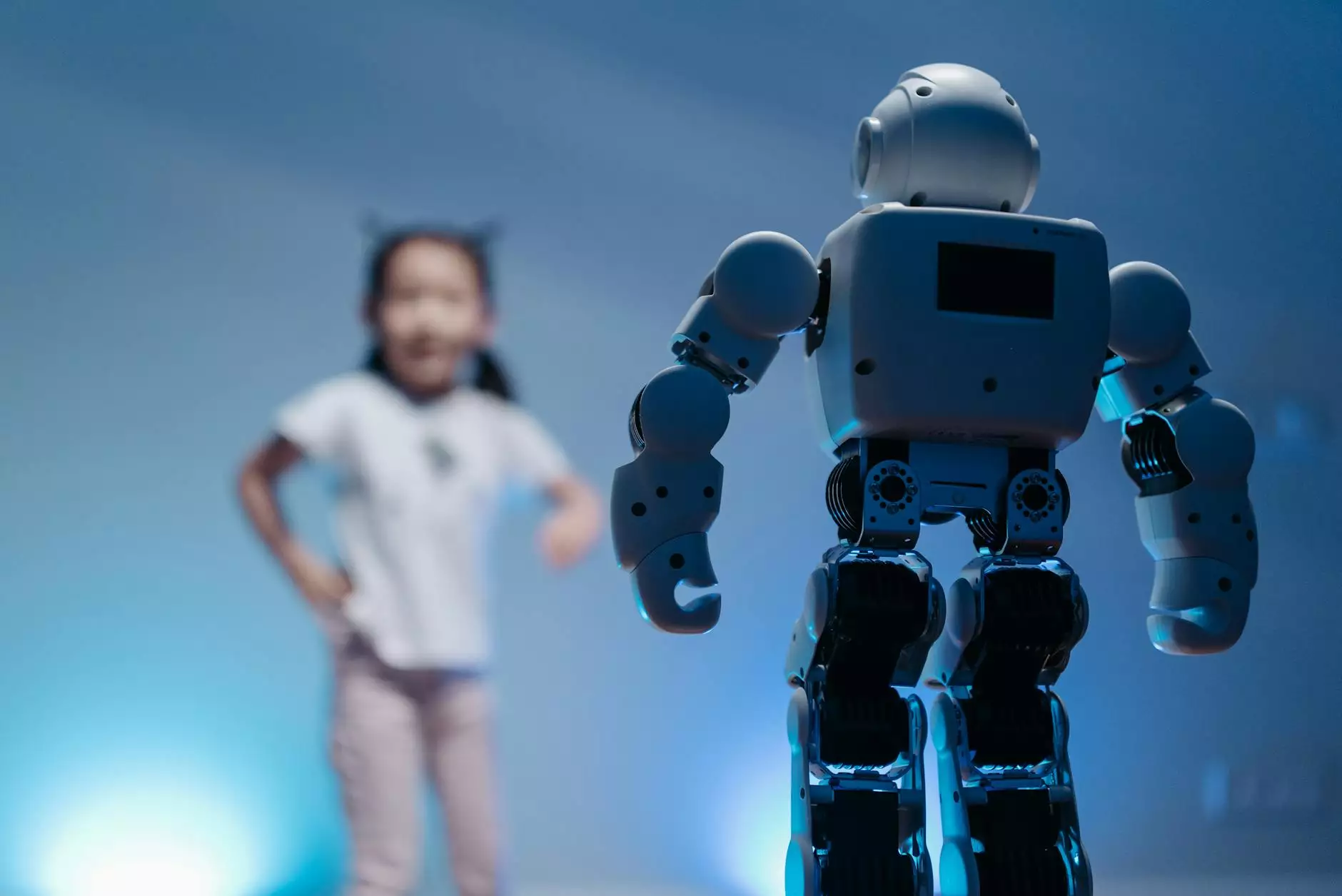

In recent years, the automotive industry has witnessed a significant transformation fueled by advancements in technology and the growing demand for custom vehicles. This evolution raises the intriguing question: are handmade cars made using robotics? The answer is a resounding yes, as innovative robotics and automation systems are increasingly being integrated into traditional craftsmanship, blending human creativity with cutting-edge technology. In this article, we will delve deep into the world of handmade cars, the role of robotics in this process, and how this intersection is shaping the future of automotive manufacturing.

The Essence of Handmade Cars

Handmade cars are often regarded as the epitome of luxury and artistry. Each vehicle is meticulously crafted by skilled artisans who pour their expertise and passion into the creation process. These cars are typically characterized by:

- Affordability: Handmade vehicles are not mass-produced, which means each one is a bespoke creation tailored to the owner's preferences.

- Unique Design: Artisans can integrate distinctive features, materials, and styles that reflect the owner's personality.

- Quality Craftsmanship: The attention to detail and traditional techniques used in crafting these vehicles often result in superior finishes and durability.

The Rise of Robotics in Automotive Manufacturing

As technology continues to advance, robotics has made its way into various industries, including automotive manufacturing. The integration of robotics into production lines has offered numerous benefits:

- Increased Efficiency: Robots can perform repetitive tasks with unmatched speed and precision, significantly reducing production times.

- Enhanced Quality Control: Automation allows for consistent quality and less variability in the manufacturing process.

- Cost-Effective Production: In the long run, robots can reduce labor costs and minimize errors, leading to savings.

How Robotics Enhances Handmade Cars

While handmade vehicles embody the spirit of craftsmanship, the incorporation of robotics does not diminish artistry; rather, it enhances the overall quality and efficiency of the process. Here are several ways in which robotics contributes to handmade car production:

Precision Manufacturing

Modern robotics can offer remarkable precision in tasks such as :

- CNC Machining: Computer Numerical Control (CNC) machines allow for intricate parts to be crafted with high levels of accuracy, ensuring that components fit perfectly.

- Automated Welding: Robotic welding systems provide consistent and strong joints that maintain the integrity of the vehicle.

Streamlining the Design Process

Robotics and automation tools help streamline the design phase of automotive manufacturing. For example:

- 3D Printing: Advanced 3D printing technology can create parts that are lightweight yet strong, contributing to the overall efficiency of handmade cars.

- Digital Prototyping: Robotics often integrates with CAD (Computer-Aided Design) systems, enabling designers to visualize and iterate their designs swiftly.

Improved Safety and Working Conditions

By utilizing robotics, manufacturers can significantly improve safety on the production floor. This can manifest in various ways:

- Reducing Manual Labor: Automation of repetitive and heavy tasks decreases the risk of injury for artisans.

- Monitoring and Maintenance: Robotics can monitor equipment conditions and perform maintenance tasks autonomously, ensuring a safer working environment.

Case Studies: Handmade Cars Using Robotics

Several car manufacturers have successfully integrated robotics in their handmade vehicle production lines. Here are a few notable examples:

Company A: Blending Artistry with Technology

Company A specializes in luxury sports cars, where each model is a one-off creation. The integration of robotic arms assists artisans in:

- Shaping Body Panels: Robotic systems help in the precise shaping of metal panels that are then hand-finished.

- Quality Assurance: High-resolution cameras paired with AI check for defects, ensuring that only flawless pieces proceed to the next stage.

Company B: Custom Electric Vehicles

Company B is known for its custom electric vehicles. Here, robotics plays a critical role in:

- Battery Assembly: Automated systems precisely assemble battery packs for optimal safety and performance.

- Interior Customization: Robots apply upholstery materials with precision, allowing for unique and customizable interiors.

The Future of Handmade Cars and Robotics

The future of automotive manufacturing seems promising, with the blending of handmade artistry and robotics paving the way for more innovative designs. As technology progresses, we can expect:

- Greater Personalization: Increased use of data analytics and AI will allow for a higher degree of customization in handmade vehicles.

- Sustainability Practices: Robotics can help optimize manufacturing processes, reducing waste and promoting sustainable production methods.

- Global Collaboration: Advanced communication technologies may enable artisans worldwide to collaborate and innovate in real-time, sharing techniques and designs.

Conclusion

The question of whether handmade cars are made using robotics reveals a fascinating trend in the automotive world. As we have explored, the combination of human craftsmanship and robotic automation is not only feasible but often enhances the final product. By integrating precision technology into handmade processes, manufacturers can achieve greater quality, efficiency, and customization.

For brands navigating the delicate balance between traditional artistry and modern technology, the road ahead is paved with potential. At fanciro.com, we look forward to seeing how this evolution unfolds, offering consumers the luxury of handmade vehicles that incorporate the best of what robotics has to offer.